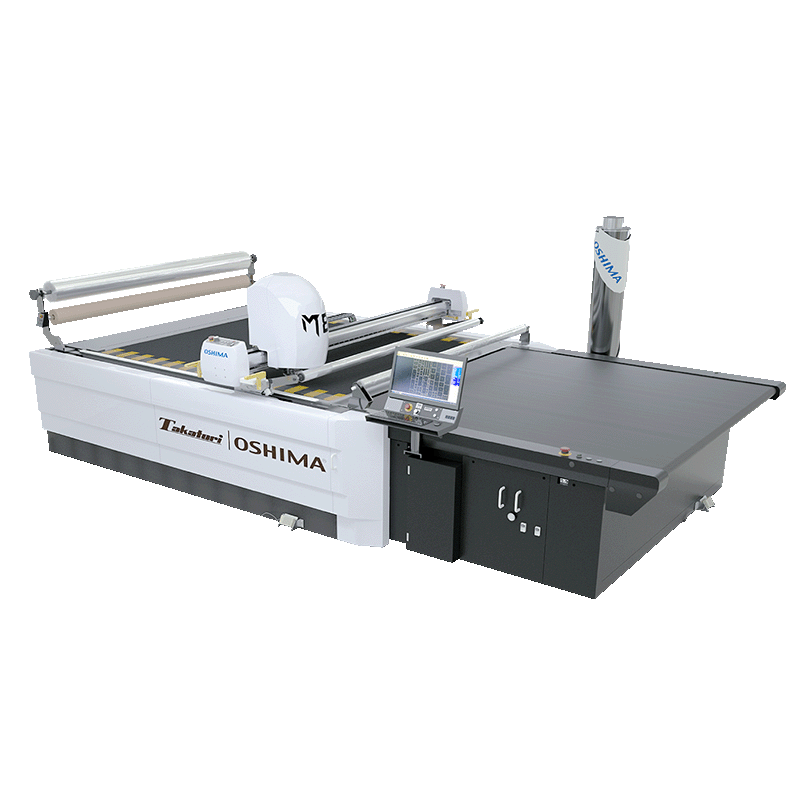

Woven Fabric Spreading F2 Dual-Flow

Ideal for headliner and lining materials

- PriceNT

- Our price:NT

- Use bonus pointspt.

Description:

F2 Dual-Flow spreading machine is specially designed for fabric spreading operations involving automotive interior materials. It is ideal for handling non-woven fabrics, foam layers, and multi-layered structured materials commonly used in headliners and interior linings. With a feed-down fabric delivery system, the machine minimizes material tension and distortion while maintaining stable tension control. It ensures smooth, wrinkle-free spreading, making it highly suitable for processes that require interlayer bonding and high-quality alignment in automotive production.

Feature

Automotive fabric compatibility- Designed for non-woven, foam, and multilayer materials

- Tailored for automotive interiors

- Handles multilayer technical textiles

Dual-roll feeding system- Maintains stable fabric tension

- Support roll-based fabric only

- Automatic edge alignment

Operational efficiency- Touchscreen control interface

- Multi-language support

- Easy to operate, even for new users

Investment- Durable and stable for long-hour operation

- Minimal wear parts

>

Specification

Model

F2 Dual-Flow-190R2

F2 Dual-Flow-210R2

Power supply

1P/220V

Motor (kW)

1.5

Maximum cloth width (mm)

1900mm/75”

2100mm/83”

Table width (mm)

2130mm/84”

2330mm/92”

Weight of cloth roll (kg)

60 (Two rolls of fabric, each weighing 30 kg.)

Diameter of cloth roll (mm)

450

Travel speed (m/min)

93

Lay height (mm)

One way 220

Face to Face 150

Spreading methods

One-way spreading (face-up)

Dimensions LxWxH (mm)

2600x1800x1200

2800x1800x1200

Packing Volume LxWxH (mm)

2800x2000x1500

3000x2000x1500

N.W/G.W (kg)

570/860

610/970

*Design and specifications subject to change without prior notice.

*Note: The loading weight and diameter of fabric rolls may vary depending on the type of fabric.

Related products

- Our price:NT

- PriceNT