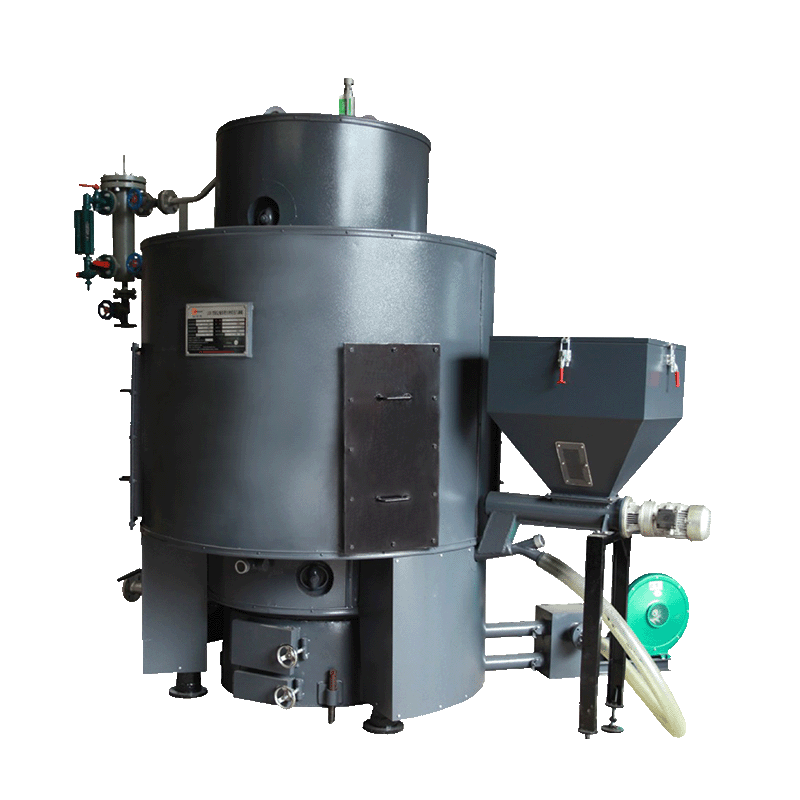

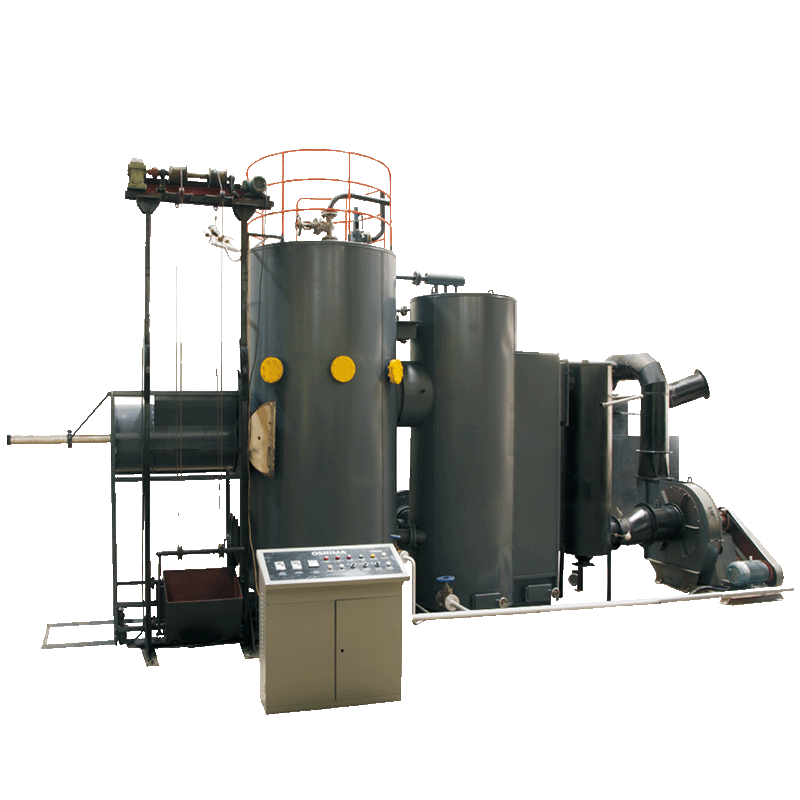

LSS Internal Combustion Biomass Boiler

Lower Costs, Lower Maintenance: The Simplified Fuel Preparation of Oshima's LSS Biomass Boiler

- PriceNT

- Our price:NT

- Use bonus pointspt.

Description:

Feature

Combustion system- Rapid cold start, fast recovery of temperature and pressure

Advanced engineering- Thermal efficiency ≥85%

- Automatic pressure, temperature and water level controls

Green and low carbon footprint- National manufacturing standards-compliant

- GB13271 emission standards

Investment cost- Auto-feeding system reduces human intervention

- Fully assembled, easy on-site installation

Cost comparison

LSS0.2-0.7 biomass steam boilers save 9 USD per hour compared to oil-fired boilers;

LSS0.3-0.7 biomass steam boiler save 16 USD per hour compared to oil-fired boilers;

LSS0.5-0.7 biomass steam boiler save 19 USD per hour compared to oil-fired boilers;

LSS0.75-0.7 biomass steam boiler save 30 USD per hour compared to oil-fired boilers;

LSS1-1.0 biomass steam boiler save 44 USD per hour compared to oil-fired boilers;

左右滑動看表格

左右滑動看表格| LSS0.2-0.7-BMF | LSS0.3-0.7-BMF | LSS0.5-0.7-BMF | LSS0.75-0.7-BM | LSS1-1.0-BMF | ||||||

| Fuel | Oil | Fuel | Oil | Fuel | Oil | Fuel | Oil | Fuel | Oil | Fuel |

| Consumption per hour kg | 14 | 37.99 | 23.5 | 56.99 | 32 | 94.98 | 49 | 142.41 | 69 | 190 |

| USD | 1.14 | 0.19 | 1.14 | 0.19 | 1.14 | 0.19 | 1.14 | 0.19 | 1.14 | 0.19 |

| Cost per hour | 16 | 7 | 26 | 11 | 37 | 18 | 56 | 27 | 79 | 35 |

Specification

左右滑動看表格

左右滑動看表格| Model | |||||||||

| LSS0.2-0.7-BMF | LSS0.3-0.7-BMF | LSS0.5-0.7-BMF | LSS0.75-0.7-BMF | LSS1-1.0-BMF | |||||

| Specification | Rated evaporation | kg/h | 200 | 300 | 500 | 750 | 1000 | ||

| Rated steam pressure | MPa | 193/204 | 1 | ||||||

| Rated steam temperature | ℃ | 170 | 184 | ||||||

| Design thermal efficiency | % | >82 | |||||||

| dust collector | Choose according to local conditions | ||||||||

| Fuel consumption | kg/h | 37.99 | 56.99 | 94.98 | 142.41 | 190 | |||

| Blower | Air volume | Nm³/h | 690 | 960 | 1404 | 1560 | 2400-3500 | ||

| Air pressure | Pa | 1880 | 1980 | 2180 | 2500 | 1834-1579 | |||

| Power | kW | 0.37 | 0.55 | 1.1 | 2.2 | 3 | |||

| Fan | Air volume | Nm³/h | 2000 | 3100 | 4000 | 5000 | |||

| Air pressure | Pa | 1372 | 2058 | 2107 | 2648 | ||||

| Power | kW | 2.2 | 3 | 5.5 | 7.5 | ||||

| Heated surface | Ontology | m² | 11.55 | 13.85 | 18.96 | 25.6 | 31.47 | ||

| Economizer | m² | 1.26 | 2 | 2.92 | 3.53 | 7.41 | |||

| Pump | Input power | kW | 1.5 | 3 | |||||

| Pipe | Main steam valve diameter | DN | 32 | 40 | 50 | ||||

| Water inlet diameter | DN | DN25 | |||||||

| Safety valve diameter | DN | G11/2" | 40 | ||||||

| Blowoff valve diameter | mm | 40 | |||||||

| Chimney | Φmm | 250 | 300 | ||||||

| Overall size | Weight | kg | 1800 | 2135 | 3267 | 4377 | 5377 | ||

| Length | mm | 1820 | 1960 | 2160 | 2500 | 2350 | |||

| Width | mm | 1400 | 1500 | 1700 | 2001 | 2200 | |||

| Height | mm | 2560 | 2790 | 3150 | |||||

Design and specifications subject to change without prior notice.

Related products

- Our price:NT

- PriceNT