- PriceNT

- Our price:NT

- Use bonus pointspt.

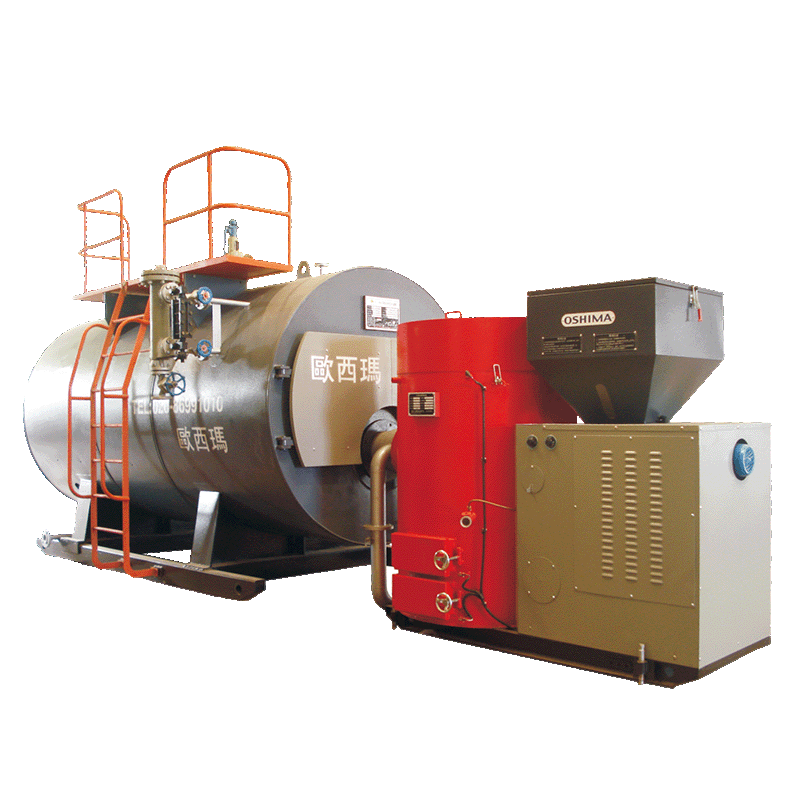

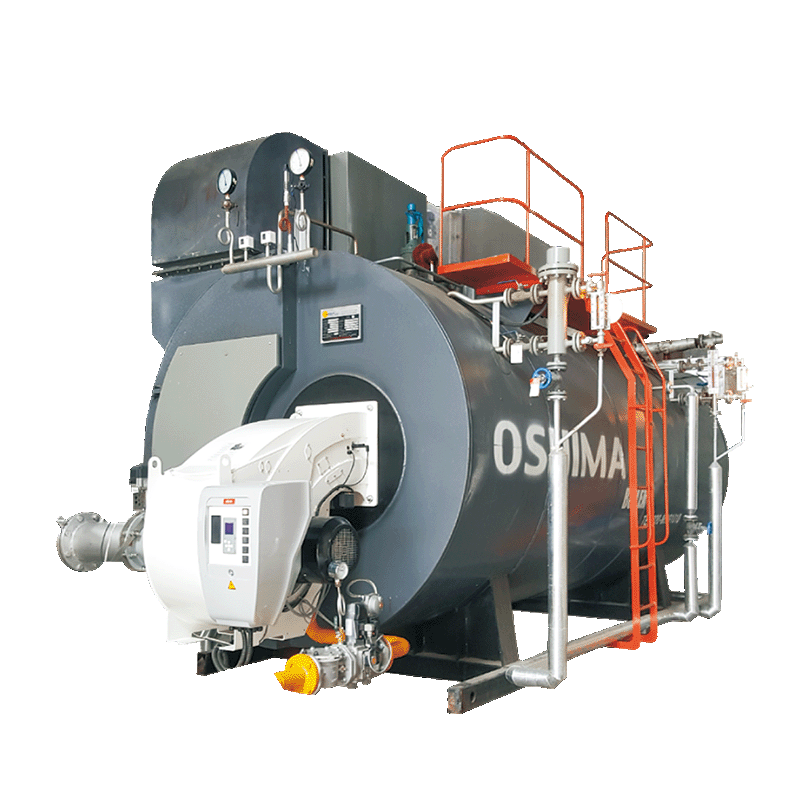

WNS (Wetback Three Pass Boiler) boilers are "shell type" boilers where the hot gases produced during combustion pass around the outside of heat-receiving tubes filled with water. The tubes are oriented horizontally, and the water absorbs heat from these gases, causing it to evaporate and create steam. This is also known as an "exchanger outside" design. The advantage of this design is that it generally has a more compact structure and can offer quicker steam production.

In simple term, WNS boilers are like having a pot of water on a stove with the flame outside the pot. The flame (hot gases) wraps around the outside of the pot (tubes filled with water), and the water heats up and turns into steam.

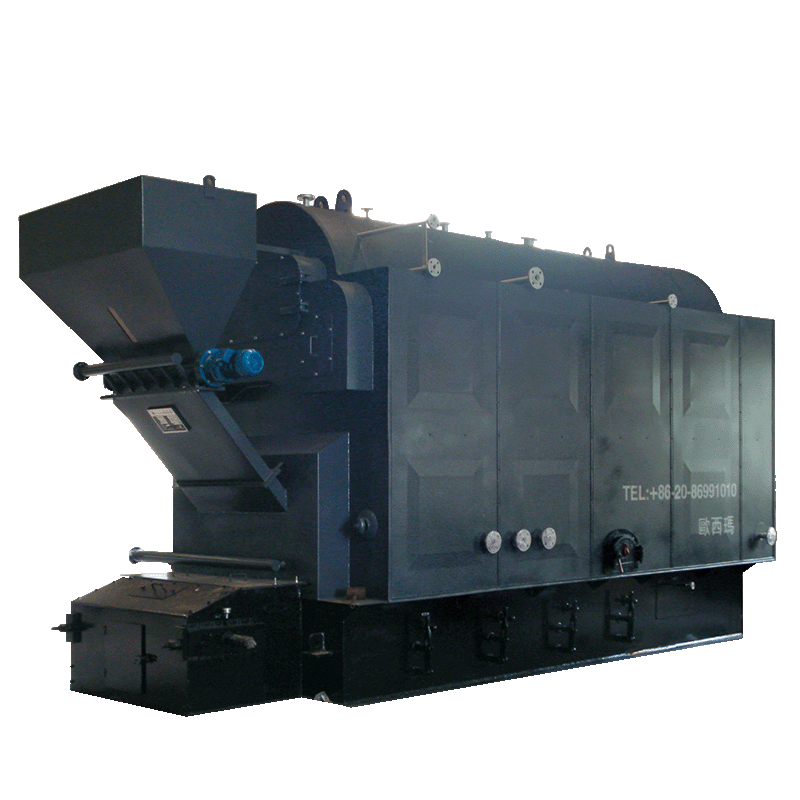

DZL/SZL boilers, on the other hand, operate on the principle of "fire tube" boilers. In this design, hot gases generated during combustion pass through the tubes that are surrounded by water. In other words, water is heated from the inside of these tubes, causing it to evaporate and produce steam. This is also known as an "exchanger inside" design. These types of boilers typically provide a higher rate of heat transfer, making them more efficient, but they might require more space due to the larger volume of water they hold.

DZL/SZL boilers are more like sticking a hot rod (tubes filled with hot gases) into a pot of water. The water is inside the pot, around the hot rod, and it heats up and turns into steam.

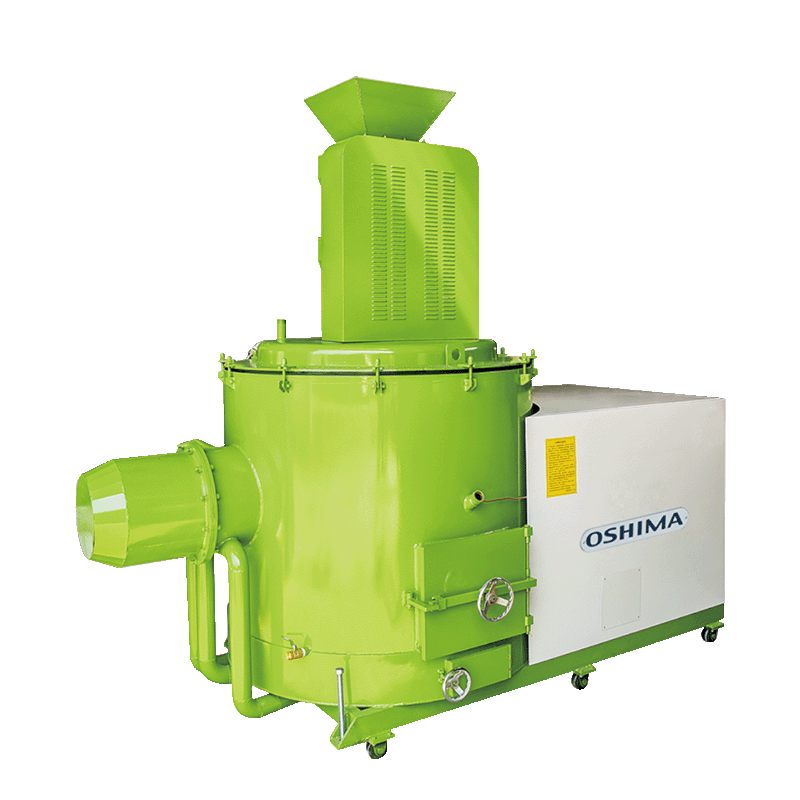

Combustion system- 100% corrugated furnace, large combustion chamber

Advanced engineering- Thermal efficiency ≥92%

- Dual fuel design

- Automatic control system

Low carbon footprint and eco-friendly- National manufacturing standards-compliant

Investment cost- Auto-feeding system reduces human intervention

- When in full use, 30-50% of fuel costs can be saved compared to traditional fossil fuels such as light diesel oil and natural gas

左右滑動看表格

左右滑動看表格| Model | ||||||||

| WNS1-1.0-BMF | WNS2-1.25-BMF | WNS3-1.25-BMF | WNS4-1.25-SC|| | WNS6-1.25-BMF | ||||

| Specification | Rated evaporation | t/h | 1 | 2 | 3 | 4 | 6 | |

| Rated steam pressure | MPa | 1 | 1.25/1.6 | |||||

| Rated steam temperature | ℃ | 184 | 193/204 | |||||

| Rated water inlet temperature | ℃ | 20 | ||||||

| Designed combustion exhaust temperature | ℃ | 160 | ||||||

| Design thermal efficiency | % | ≥92 | ||||||

| Fuel consumption | kg/h | 190 | 380 | 570 | 770 | 1140 | ||

| Water volume | L | 2832 | 4520 | 6900 | 7300 | 7677 | ||

| Heated surface | ||||||||

| Ontology | m³ | 24.5 | 50.6 | 81.9 | 100.7 | 162.3 | ||

| Economizer(Fin-tube atmospheric pressure) | m³ | 12.9 | 21 | 27 | / | |||

| Economizer(Steel pipe atmospheric boiler) | m³ | / | 23 | 32 | ||||

| Pump | Input power | kW | 3 | 4 | 4 | 7.5 | 7.5 | |

| Pipe | Main steam valve diameter | DN | 50 | 80 | 100 | 125 | ||

| Water inlet diameter | DN | 25 | 32 | 40 | ||||

| Safety valve diameter | DN | 50 | 65 | 50*2 | 65*2 | |||

| Blowoff valve diameter | mm | 40 | 50 | 50*2 | ||||

| Chimney | Φ | 300 | 350 | 400 | 450 | 500 | ||

| Overall size | Weight | t | 4.6 | 7.6 | 11.2 | 12.5 | 17.6 | |

| Length | mm | 3840 | 4620 | 5136 | 5840 | 6334 | ||

| WIdth | mm | 1760 | 1980 | 2300 | 2230 | 2432 | ||

| Height | mm | 2064 | 2190 | 2718 | 2770 | 2872 | ||

- Our price:NT

- PriceNT