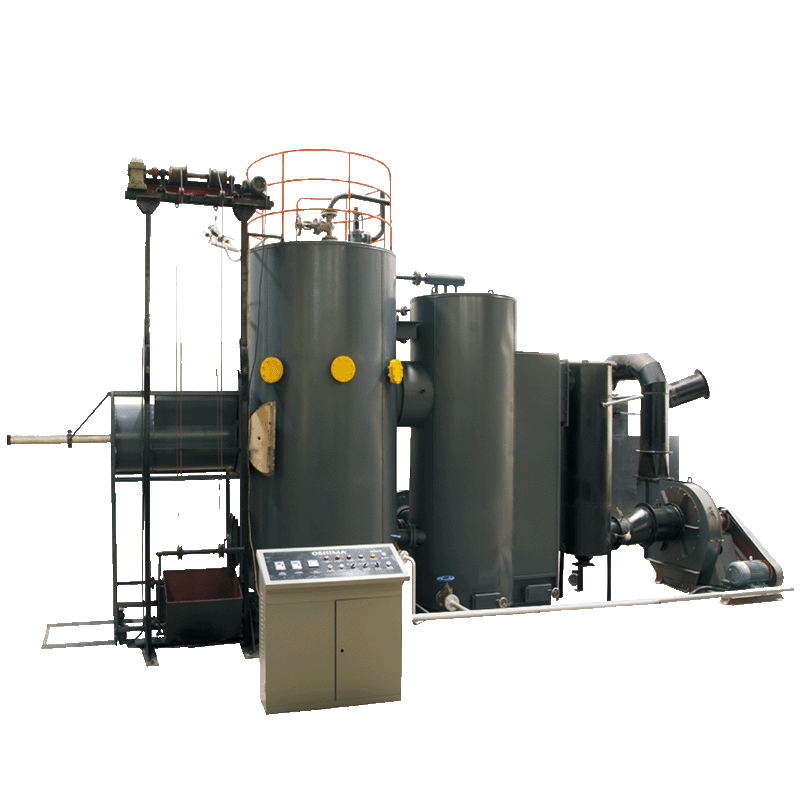

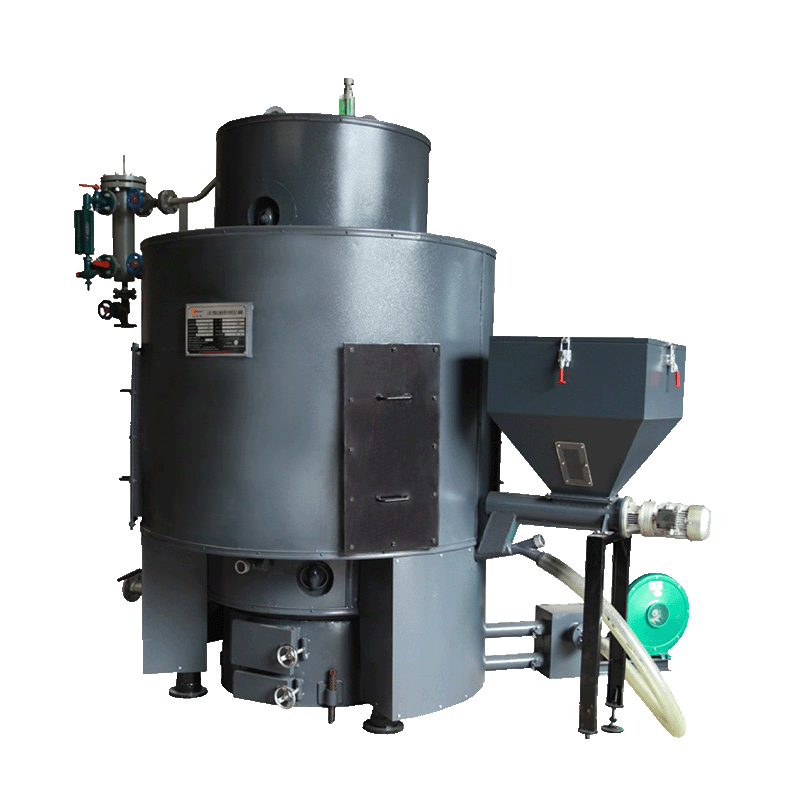

LSG Biomass Combustion

Efficiency Meets Affordability: Our Biomass Boiler Solution

- PriceNT

- Our price:NT

- Use bonus pointspt.

Description:

Feature

Combustion system- Vertical furnaces optimize combustion

Advanced engineering- Thermal efficiency ≥85%

- Dual fuel design

- Automatic Control System

Green and low carbon footprint- National manufacturing standards-compliant

Investment cost- Auto-feeding system reduces human intervention

- Fully assembled, easy on-site installation

- Few accessories require little upkeep

Specification

左右滑動看表格

左右滑動看表格| Model | |||||

| LSG1-0.8-FL | LSG1.5-0.8-FL | LSG2-0.8-FL | |||

| Specification | Rated evaporation | kg/h | 1000 | 1500 | 2000 |

| Rated steam pressure | MPa | 0.8 | |||

| Rated steam temperature | ℃ | 175 | |||

| Exhaust temperature | ℃ | ≤230 | |||

| Water temperature | ℃ | 20 | |||

| Boiler water volume | m³ | 2.8 | 3.3 | 3.6 | |

| Total power consumption | kg | 18 | 25 | 33 | |

| Insulation soft water tank volume | m³ | 2 | 3 | ||

| Design thermal efficiency | % | 88 | |||

| Heat of combustion | kcal | 4600 | |||

| Fuel consumption | kg/h | 160 | 240 | 320 | |

| Blower | 9-26-4.5A-7.5KW | 9-26-4.5A-11KW | 9-26-5A-15KW | ||

| Fan | Y6-30-7.5C-7.5Kw | Y6-30-7.5C-11Kw | Y6-30-7.5C-7.5Kw | ||

| Heated surface | Ontology | m² | 40 | 53 | 65 |

| Pump | Input power | kW | 3P 380V | ||

| Pipe | Main steam valve diameter | DN | 50 | 65 | |

| Water inlet diameter | DN | 40 | 50 | ||

| Safety valve diameter | DN | 40 | 50 | 65 | |

| Blowoff valve diameter | mm | 40 | |||

| Chimney | Φmm | 350 | 400 | ||

| Installation size | Length | mm | 10000 | 11000 | 12000 |

| Width | mm | 6000 | 6500 | ||

| Height | mm | 5500 | 6000 | ||

| Maximum shipping size | Length | mm | 1850 | 2050 | |

| Width | mm | 1850 | 2050 | ||

| Height | mm | 3600 | 3700 | 3950 | |

| Remarks: Without automatic feeding, the length can be reduced by 1500mm; if the boiler room is less than the recommended size, the length can be reduced by 500mm respectively | |||||

Design and specifications subject to change without prior notice.

Related products

- Our price:NT

- PriceNT