- PriceNT

- Our price:NT

- Use bonus pointspt.

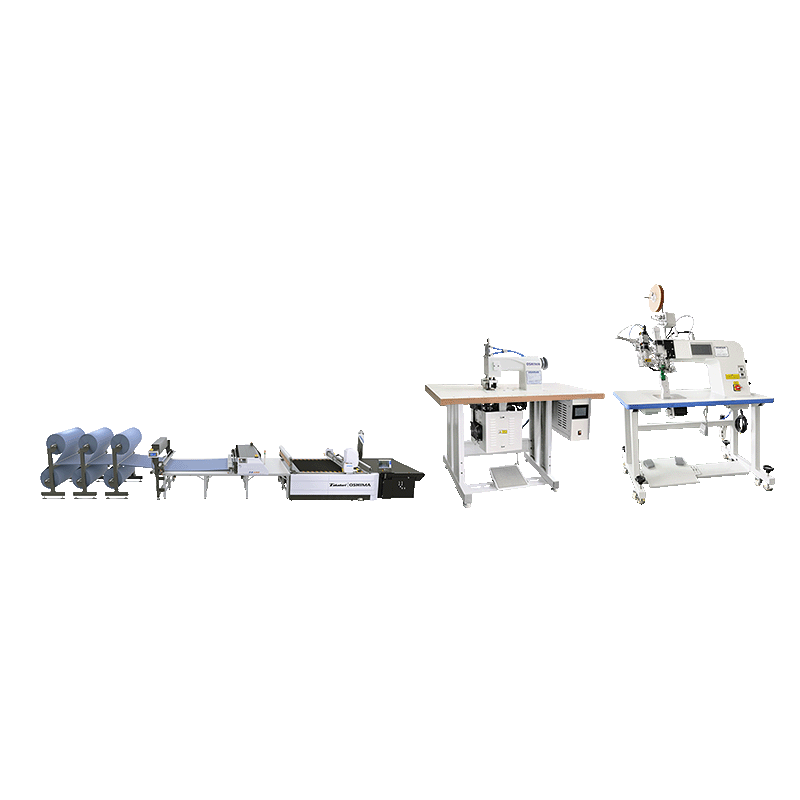

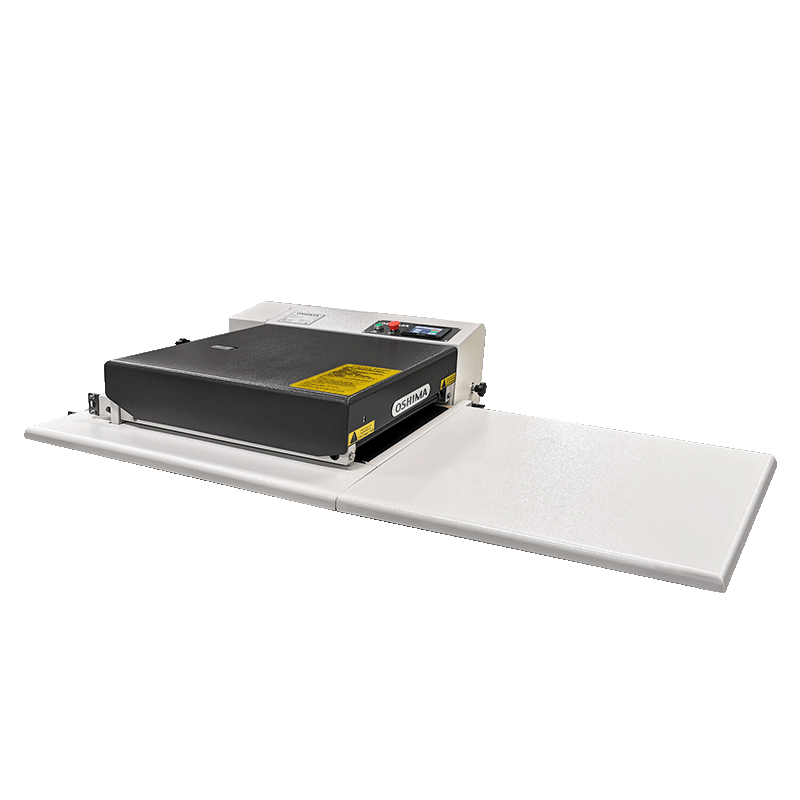

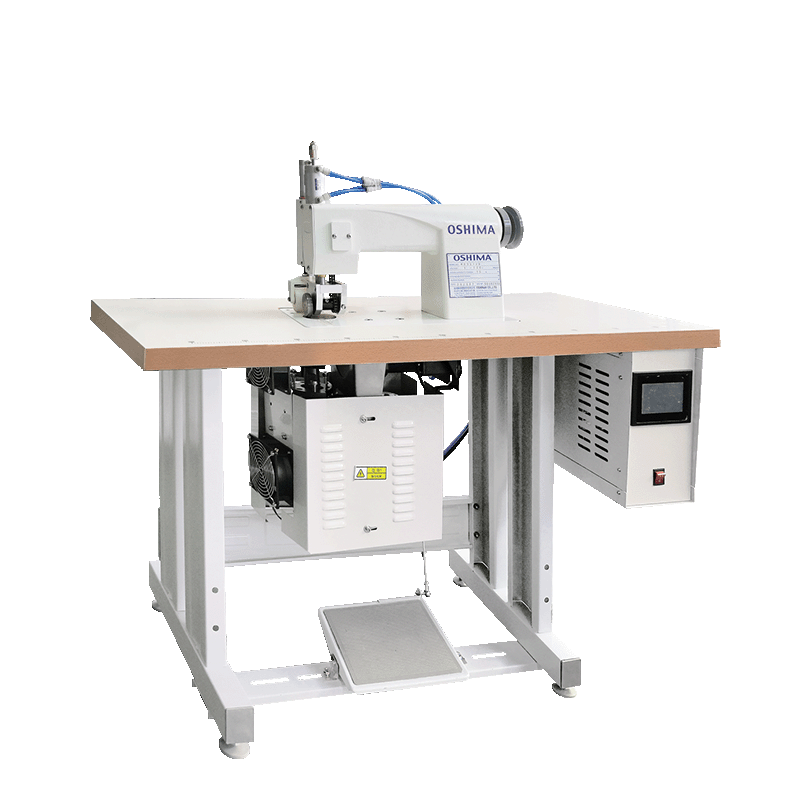

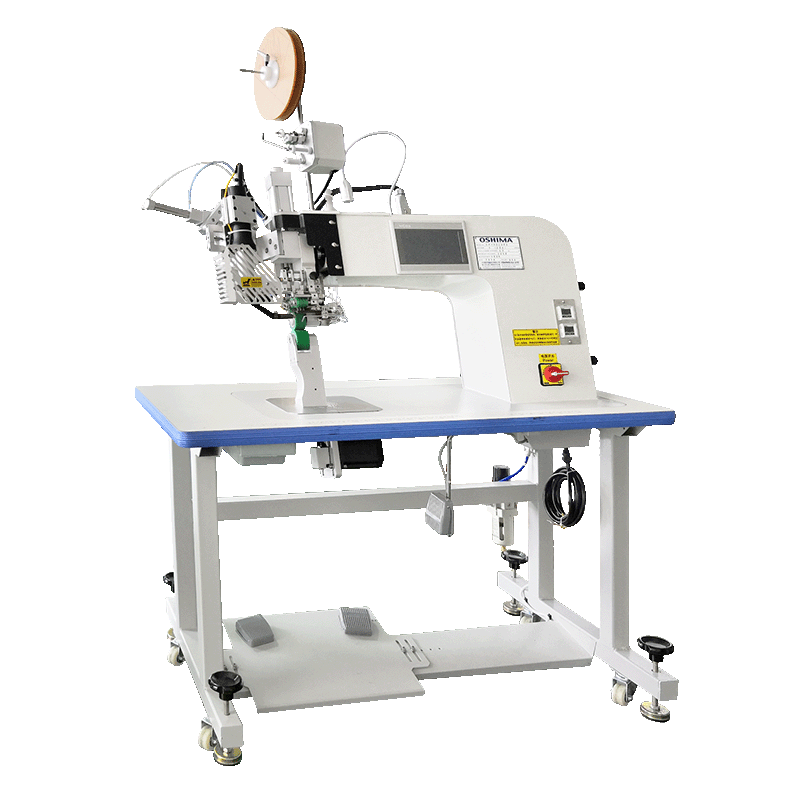

OSHIMA garment machinery, which includes automatic fabric spreading and cutting machines, fusing machines, ultrasonic cutting, and hot air sealing technologies, is designed to considerably improve the manufacturing capacity of the medical products industry. These modern machines are perfect for the speedy production of key medical items such as gowns, masks, medical linens, and personal protective equipment (PPE), which is especially important in emergency situations. Ultrasonic cutting enables the clean and precise finishing of textile edges, which is critical for medical applications like masks. Furthermore, the integration of hot air sealing enables the application of waterproof adhesive strips using a hot melting process. This method is highly effective in preventing liquid penetration at fabric seams, thereby ensuring the waterproofness and safety of the manufactured items, while also minimizing the risk of skin irritation. OSHIMA's machinery gives the garment manufacturing industry a competitive advantage in supplying high-quality medical supplies quickly, demonstrating its critical role in responding to public health catastrophes.

- Our price:NT

- PriceNT