- PriceNT

- Our price:NT

- Use bonus pointspt.

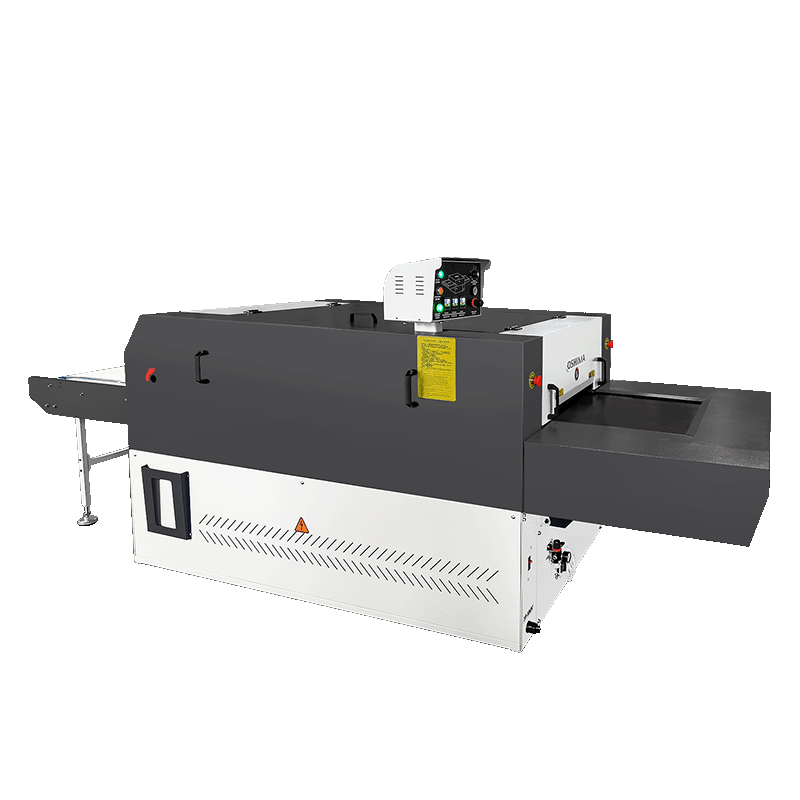

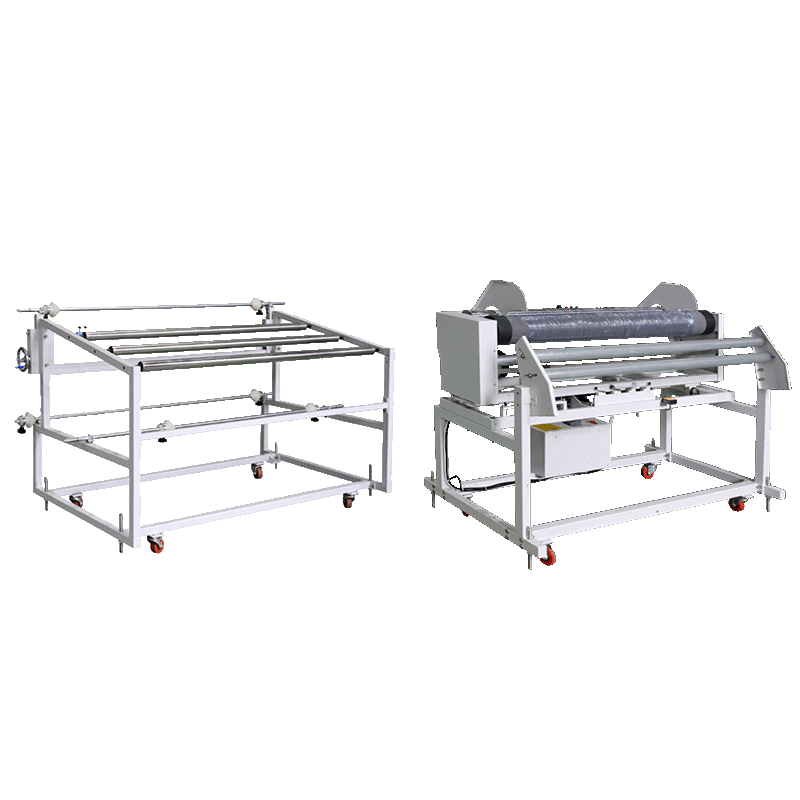

The N Series was designed to minimize shrinkage in soft and elastomeric fabrics. The maximum pressure is 10KG. Discover the high quality of our fabric fusing machine, which is intended for maximum adhesion on delicate and elastic materials. The use of a pneumatic cylinder system ensures consistent pressure distribution on the drum. Its computer-controlled three-stage heating system provides accurate temperature control, while the monitoring system enables continuous heat generation and immediate adjustment. The machine detects and troubleshoots anomalies for a hassle-free operation. The vacuum cooling system enables quick cooling and shaping after bonding, resulting in perfect finishes. Perfect for high-temperature and highly elastic fabrics, such as seamless innerwear. For mobility, the machine incorporates movable wheels.

- Our price:NT

- PriceNT